What is a Valve Guide? A Comprehensive Overview (Updated 02/03/2026)

Valve guides are essential engine components, precisely aligning valves and ensuring correct function, supporting valve stems and aiding heat dissipation for optimal performance.

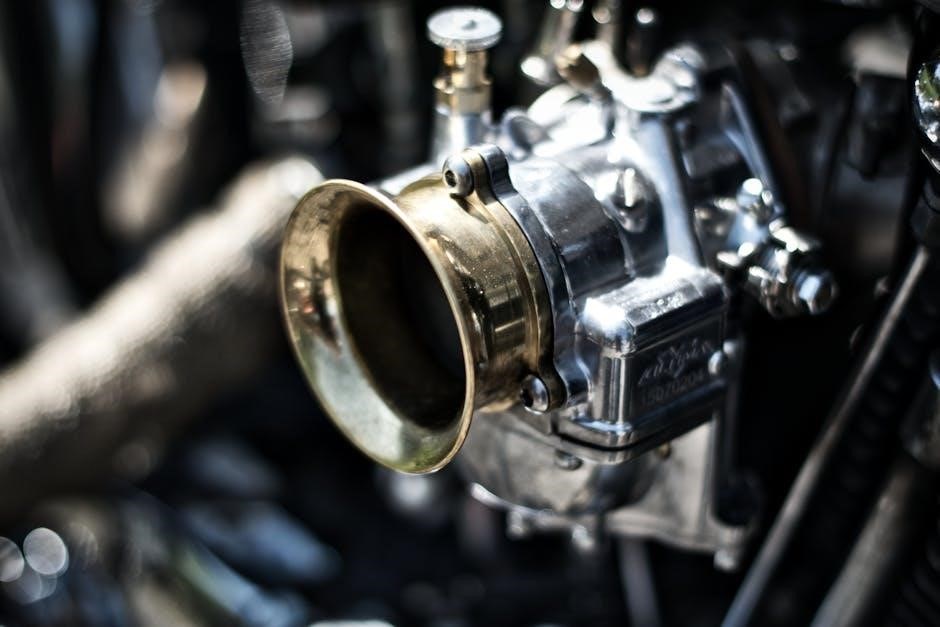

Valve guides represent a critical, yet often overlooked, component within the intricate system of an internal combustion engine. These cylindrical components are strategically positioned within the engine cylinder head, serving as a precise pathway and support structure for the engine’s valves. Their primary role is to ensure accurate valve movement, facilitating the controlled intake of air and fuel mixtures, and the efficient expulsion of exhaust gases – processes fundamental to engine operation.

Without properly functioning valve guides, maintaining optimal engine performance and longevity becomes significantly challenging. They aren’t merely passive conduits; they actively contribute to the engine’s overall efficiency and reliability. Understanding their function and construction is key to appreciating their importance in modern automotive engineering.

The Role of Valves in Internal Combustion Engines

Valves are the gatekeepers of the combustion process within an internal combustion engine, orchestrating the precise timing of air and fuel intake, and exhaust expulsion. Their rhythmic opening and closing, synchronized with the engine’s rotation, is paramount for efficient operation. However, valves don’t operate in isolation; they rely heavily on the support and guidance provided by valve guides.

These valve guides ensure the valves maintain correct alignment, preventing unwanted contact with other engine components and maximizing sealing efficiency. A properly functioning valve system, facilitated by robust valve guides, directly translates to improved engine power, fuel economy, and reduced emissions. The interplay between valves and valve guides is therefore fundamental to engine performance.

Valve Guide Functionality & Importance

Valve guides center valves, compensate for lateral forces on valve shafts, and assist with heat removal, ensuring stable valve stem operation and engine efficiency.

Precise Valve Alignment

Valve guides are fundamentally critical for maintaining accurate valve alignment within the cylinder head. This precision is not merely a matter of proper seating; it directly impacts volumetric efficiency and overall engine performance. Without correctly aligned valves, the combustion process suffers, leading to reduced power output and increased emissions.

The valve guide’s internal diameter must closely match the valve stem diameter, creating a stable and controlled relationship. This tight fit prevents valve wobble and ensures the valve face seals effectively against the valve seat. Misalignment can cause uneven wear on both the valve and the seat, ultimately leading to compression loss and requiring costly repairs. Proper alignment also minimizes the risk of valve-to-piston contact, a potentially catastrophic engine failure.

Compensation for Lateral Forces

Internal combustion engines subject valves to significant lateral forces during operation, stemming from the angled valve pushrods or rocker arms, and the reciprocating motion of the valve spring. Valve guides are engineered to effectively counteract these forces, preventing undue stress on the valve stem and ensuring smooth, consistent valve movement.

Without adequate support, these lateral loads would cause premature valve stem wear, leading to valve guide erosion and eventual valve failure. The valve guide acts as a robust bushing, absorbing and distributing these forces across a larger surface area of the cylinder head. This protective function is crucial for maintaining engine reliability and extending component lifespan, especially in high-performance applications where these forces are amplified.

Heat Dissipation from the Valve

The combustion process within an internal combustion engine generates substantial heat, and valves are directly exposed to these extreme temperatures. Efficient heat dissipation is vital to prevent valve distortion, cracking, and premature failure. Valve guides play a significant role in transferring heat away from the valve stem and into the cylinder head, which is typically cooled by the engine’s coolant system.

The close contact between the valve stem and the valve guide facilitates conductive heat transfer. The guide’s material, often cast iron or bronze, is chosen for its thermal conductivity properties. By channeling heat away from the valve, the valve guide helps maintain optimal valve operating temperatures, contributing to improved engine efficiency and longevity, especially under demanding conditions.

Maintaining Valve Stem Stability

A critical function of valve guides is to provide unwavering stability to the valve stem throughout its entire range of motion. Without precise guidance, the valve stem could wander laterally, leading to improper sealing against the valve seat and resulting in compression loss, reduced engine power, and potential damage to other engine components.

The valve guide’s internal diameter is meticulously machined to create a close, yet smooth, fit with the valve stem. This precise fit minimizes wobble and ensures the valve remains perfectly aligned during opening and closing cycles. Maintaining this stability is paramount for consistent engine performance and preventing premature wear on both the valve stem and the valve guide itself, ultimately extending engine life.

Types of Valve Guides

Valve guides come in diverse types, including cylindrical bushes, one-piece designs, two-piece constructions, and advanced roller valve guides, each offering unique benefits.

Cylindrical Metal Bushings

Cylindrical metal bushings represent a traditional and widely utilized type of valve guide, particularly effective in supporting inlet valves within an internal combustion engine. These guides are characterized by their simple, yet robust, design – essentially a cylindrical sleeve pressed into the cylinder head. Constructed from materials like cast iron or bronze, they provide a smooth, low-friction surface for the valve stem to reciprocate within, ensuring precise alignment and minimizing wear.

Their primary function is to center the valve, preventing it from tilting or binding during operation. This precise centering is crucial for maintaining a tight valve seal against the valve seat, which is essential for efficient combustion and preventing exhaust gas leakage. While relatively straightforward in their construction, cylindrical bushings offer a cost-effective and reliable solution for valve guidance in many engine applications, contributing significantly to overall engine performance and longevity.

One-Piece Valve Guides

One-piece valve guides represent a design approach where the valve guide is manufactured as a single, integrated component, typically machined directly from the cylinder head material or cast as a single unit. This contrasts with multi-piece designs, offering enhanced structural rigidity and potentially improved heat transfer characteristics. These guides are commonly found in engine designs prioritizing durability and reduced manufacturing complexity.

The inherent strength of a one-piece construction minimizes the risk of loosening or shifting over time, contributing to long-term valve alignment and consistent engine performance. While offering benefits in terms of robustness, manufacturing one-piece valve guides can be more challenging, requiring precise machining and careful consideration of thermal expansion properties. They effectively center the valve, ensuring proper sealing and contributing to efficient combustion within the engine.

Two-Piece Valve Guides

Two-piece valve guides offer a distinct construction method, typically comprising a pressed-in or interference-fit inner liner within an outer sleeve, providing a combination of wear resistance and ease of replacement. This design allows for the use of different materials for each component, optimizing performance and cost-effectiveness. The inner liner, often made from a hardened alloy, directly contacts the valve stem, while the outer sleeve provides structural support and securement within the cylinder head.

This modular approach simplifies valve guide replacement during engine maintenance, as only the worn inner liner needs to be exchanged, reducing labor and component costs. However, the interface between the two pieces requires careful attention to ensure a robust and reliable connection, preventing movement or separation during engine operation. They still effectively center the valve, maintaining proper alignment.

Roller Valve Guides

Roller valve guides represent a more advanced valve control technology, designed to minimize friction and wear between the valve stem and the guide itself. Instead of a direct sliding contact, these guides utilize small rollers or needle bearings positioned between the valve stem and the guide bore, significantly reducing frictional forces during valve movement. This design is particularly beneficial in high-performance engines where precise valve control and reduced power loss are critical.

By minimizing friction, roller valve guides contribute to improved engine efficiency, increased horsepower, and reduced valve stem wear. However, they are generally more complex and expensive than traditional valve guides, requiring precise manufacturing and installation. They still perform the core function of centering the valve, but with enhanced smoothness and durability.

Valve Guide Materials

Valve guides are commonly crafted from grey cast iron, brass, or sintered metals, each alloy carefully chosen to withstand specific engine loads and temperatures.

Grey Cast Iron Valve Guides

Grey cast iron valve guides represent a traditional and widely utilized material choice due to their excellent wear resistance and inherent damping capabilities. This composition effectively minimizes noise generated during valve operation, contributing to smoother engine performance. The material’s structure allows for good machinability, simplifying the manufacturing process and reducing production costs. However, grey cast iron possesses relatively lower tensile strength compared to other options, potentially limiting its suitability for high-performance applications experiencing extreme stresses.

Despite this limitation, its affordability and adequate performance in standard engines make it a popular selection. The iron’s ability to embed small amounts of debris also contributes to lubrication, further extending the guide’s lifespan. Careful consideration of engine specifications and operating conditions is crucial when determining if grey cast iron is the appropriate material for a specific valve guide application, balancing cost-effectiveness with durability requirements.

Brass Valve Guides

Brass valve guides offer a compelling alternative to cast iron, primarily due to their superior embeddability and enhanced resistance to corrosion. This inherent property allows brass guides to better accommodate minor debris and maintain a smoother surface finish, reducing friction and wear on the valve stem. The material’s excellent lubricity further contributes to prolonged valve guide life, particularly in environments where maintaining optimal lubrication is challenging.

However, brass generally exhibits lower tensile strength and thermal conductivity compared to cast iron or more advanced materials. This can be a limiting factor in high-performance engines generating significant heat. Despite this, brass remains a viable option for many applications, especially where corrosion resistance and smooth operation are paramount. Careful alloy selection within the brass family can optimize performance characteristics for specific engine requirements, balancing durability with cost-effectiveness.

Sintered Metal Valve Guides

Sintered metal valve guides represent a modern manufacturing approach, utilizing powdered metal compacted into a precise shape. This process allows for intricate designs and controlled porosity, offering unique advantages in valve guide performance. The ability to tailor material composition and density during sintering enables engineers to optimize properties like wear resistance, lubricity, and thermal conductivity.

Sintered guides often incorporate oil reservoirs within their structure, providing continuous lubrication to the valve stem, reducing friction and extending component life. Different alloy compositions are employed to suit varying load and temperature conditions. While generally offering excellent dimensional accuracy and consistent quality, sintered guides may exhibit lower strength compared to solid-machined alternatives. However, advancements in sintering technology are continually improving their mechanical properties, making them increasingly popular in modern engine designs.

Manganese Bronze Valve Guides

Manganese bronze valve guides are a traditional choice, renowned for their excellent wear resistance and inherent lubricity. The alloy composition, featuring manganese, bronze, and often other elements like aluminum, creates a material that performs exceptionally well under high loads and temperatures. This makes them particularly suitable for applications where durability and reliability are paramount.

Manganese bronze exhibits good thermal conductivity, aiding in the dissipation of heat from the valve stem, contributing to reduced valve temperatures and improved engine efficiency. These guides are typically machined to precise dimensions, ensuring a tight fit within the cylinder head and accurate valve alignment. While offering superior performance characteristics, manganese bronze can be more expensive than some alternative materials like cast iron, but the extended service life often justifies the initial investment.

Valve Materials: Road Spec

For standard road-going vehicles, valve materials historically prioritized longevity and cost-effectiveness. Early designs featured plain finished stems and seats, benefiting from the protective properties of leaded fuel – now obsolete. These older “road spec” valves, paired with appropriate valve guides, were designed for typical driving conditions and moderate engine temperatures.

Modern road spec valves often utilize improved alloys and surface treatments to compensate for the lack of lead in fuel, enhancing durability and resistance to wear. The valve guides used with these materials must complement their properties, typically employing materials like cast iron or bronze to ensure smooth operation and prevent premature failure. The focus remains on reliable performance and extended service intervals for everyday use.

Valve Materials: Up-rated Road Spec

Moving beyond standard road specifications, “up-rated” valves represent a performance enhancement for street vehicles experiencing increased stress. These valves often feature improved material compositions and more sophisticated surface treatments, demanding valve guides capable of handling higher loads and temperatures; The goal is to provide increased durability and improved flow characteristics without sacrificing the reliability needed for daily driving.

These upgraded components frequently utilize alloys designed to resist wear and deformation under demanding conditions. Correspondingly, the valve guides must be selected to match this enhanced performance, often incorporating materials like manganese bronze or specialized sintered metals. This ensures precise alignment and minimizes friction, contributing to improved engine efficiency and responsiveness.

Valve Materials: Race Spec

Race-specification valves represent the pinnacle of engine component engineering, prioritizing ultimate performance and durability under extreme conditions. These valves demand valve guides engineered to withstand incredibly high stresses, temperatures, and speeds. Materials are carefully selected for their strength, lightweight properties, and resistance to wear, often involving exotic alloys and advanced coatings.

Consequently, the valve guides used with race valves must provide unwavering precision and stability. Materials like high-performance bronzes or specialized steel alloys are common, frequently incorporating surface treatments to minimize friction and maximize heat transfer. The tolerances are exceptionally tight, ensuring optimal valve control and preventing premature failure during intense racing applications. Reliability is paramount, as even minor component failures can lead to catastrophic engine damage.

Valve Guide Installation & Maintenance

Proper installation and consistent maintenance of valve guides are crucial for engine longevity, ensuring correct fitting positions and addressing wear and tear promptly.

Proper Fitting Positions

Achieving optimal engine performance hinges on the precise positioning of valve guides within the cylinder head. These guides aren’t simply dropped in; they require careful alignment and specific interference fits to ensure stability and accurate valve control. The correct depth and orientation are paramount, dictated by the engine’s design and valve geometry.

Manufacturers specify precise locations for each valve guide, considering factors like combustion chamber shape and valve angles. Incorrect positioning can lead to valve misalignment, impacting sealing and potentially causing engine damage. Furthermore, the interference fit – the slight compression required during installation – creates a secure bond, resisting movement under the stresses of engine operation. Specialized tools are often employed to ensure consistent and accurate installation, guaranteeing long-term reliability and optimal valve train function.

Valve Guide Wear and Tear

Valve guides, despite being constructed from durable materials, are inevitably subject to wear and tear during engine operation. Constant contact with the valve stem, coupled with the intense heat and friction within the combustion chamber, gradually erodes the guide’s inner surface. This wear manifests as increased valve stem-to-guide clearance, leading to valve instability and reduced sealing efficiency.

Factors accelerating wear include poor lubrication, abrasive contaminants in the oil, and high engine speeds. Over time, excessive clearance can cause valve float, oil consumption, and ultimately, engine performance degradation. Regular inspection is crucial to detect early signs of wear, such as valve stem wobble or excessive oil burning, allowing for timely intervention and preventing more significant engine damage. Ignoring wear compromises the engine’s overall reliability.

Signs of a Failing Valve Guide

Detecting a failing valve guide early is crucial for preventing extensive engine damage. Several telltale signs indicate potential issues. Noticeable blue smoke from the exhaust, particularly during acceleration, often signals oil entering the combustion chamber due to worn guide seals. A ticking or clicking noise emanating from the valve train can also indicate valve stem play caused by excessive guide clearance.

Furthermore, reduced engine compression, misfires, and a general loss of power are common symptoms. A visual inspection may reveal oil buildup around the valve stems. If a valve exhibits noticeable wobble when manually manipulated, the guide is likely worn. Addressing these signs promptly through inspection and potential replacement ensures continued engine health and prevents more costly repairs down the line.

Valve Guide Replacement Procedures

Valve guide replacement demands precision and careful execution. The process typically begins with cylinder head disassembly, removing the valves and associated components. Old guides are often pressed or driven out using specialized tools, requiring careful alignment to avoid head damage. The new guides are then typically installed using a similar method, often after chilling the head to facilitate a tight fit.

Following installation, reaming or honing the guide’s inner diameter to the correct valve stem clearance is essential. Accurate measurements are critical throughout. Finally, the valves are reinstalled, and the cylinder head is reassembled, ensuring proper valve lash adjustment. Professional expertise is highly recommended to guarantee a successful and reliable repair.

Advanced Valve Guide Technologies

Coated valve guides and high-performance materials enhance durability and heat transfer, improving valve control and engine efficiency for demanding applications and longevity.

Coated Valve Guides

Coated valve guides represent a significant advancement in engine technology, addressing the challenges of wear, heat, and friction within the internal combustion engine. These guides utilize a base material – often a durable metal alloy – enhanced by a specialized coating applied to the inner surface where contact with the valve stem occurs. The primary purpose of this coating is to reduce friction, minimizing wear on both the guide and the valve stem itself, ultimately extending the lifespan of these critical components.

Various coating materials are employed, including chrome, ceramic, and specialized polymers, each offering unique properties. Chrome coatings provide excellent wear resistance, while ceramic coatings excel at thermal management, dissipating heat more effectively. Polymer coatings can offer a low-friction surface, further reducing wear and improving valve operation. The application of these coatings is a precise process, ensuring a uniform and durable layer that withstands the harsh conditions within the engine cylinder. Ultimately, coated valve guides contribute to improved engine performance, reduced emissions, and increased reliability.

High-Performance Valve Guide Materials

High-performance valve guide materials are crucial for engines subjected to extreme conditions, such as racing or heavily modified street applications. Traditional materials like cast iron and brass often fall short under these stresses, necessitating the use of advanced alloys designed for superior durability and heat resistance. Materials like manganese bronze offer enhanced strength and wear characteristics, proving suitable for demanding environments.

However, truly high-performance applications frequently employ specialized alloys containing nickel, silicon, and chromium, engineered to withstand intense heat and maintain precise dimensional stability. Sintered metal valve guides, utilizing powder metallurgy, allow for complex alloy compositions and controlled porosity, optimizing both strength and lubrication. The selection of the appropriate material depends heavily on the specific engine application and the anticipated operating parameters, ensuring optimal valve control and longevity under extreme loads and temperatures.